Much of the information presented here following this new development will now be obsolete. I will not remove anything for now; something may still be good reference.

- Piper Service Bulletin SB-1189 Stabilator Horn Assembly Inspection.

- Piper Service Bulletin SB-1189-88372 Kit, Torque Tube replacement.

- FWIW DEPARTMENT – tube kits availability so-says-Piper, Feb to Apr 2011; but they’ve lied about other things too :). I’ve been waiting since Sept 2010 for tube kits.

So there you have it folks, why would anyone dare tackle the SB-1189 without parts?

To see photographs of the cracked torque tube horns mentioned below by Hans, open this link informative article by Denny Haskins.

This concerns all Comanche models; the torque tube horn forging.

[Now a not-so] RED HOT ISSUE – from Hans Neubert, read below.

Since many Comanche owners don’t visit either site, we need to have volunteers at each airport that has Comanche aircraft to help them fill out spare questionnaires.

Let me give everyone the reasons for the questionnaire in the first place.

- Collecting and maintaining the database on horn inspections and findings has been insufficient. Creating and mailing in the form is much more concise and current with the information needed.

- In the draft phase, Piper/FAA were talking about repetitive inspections every 100 hours. My response was that 100 hours was unnecessary and potentially damaging to the airframe. With enough data to justify, I’ll be arguing to get 1000 hours or 10 years, whichever comes first.

- I want to make sure that those that have made the inspection, that they get credit for it, retroactively.

- If the data supports the conclusion, I would like to eliminate certain models, except for a one-time inspection, unless done already.

- For those that have replaced their horns, that they get credit for that, and not be required to inspect again until the time/hour limit in #2 is reached.

How much data do I need? I estimate that there 4660 Comanches registered, world wide. I need to have at least 1000 inspection questionnaires in order to make a presentable case. Anything less, and we are at the will of the authorities.

So, do your part, and get the information on every Comanche at your airport, and send it in. There are more cracked horns out there.

Be assured, since a cracked horn is an airworthiness issue (not maintenance, like the corroded torque tube), an AD will come. I will do my part if Comanche owners unite and do their part.

The Comanche Stabilator has a few issues; here is a list and links. This may not be complete, it is from my research. If you are aware of something that should be here for the good of all, please contact me.

- Airworthiness Directive 74-13-03

- Airworthiness Directive 76-19-07

- Airworthiness Directive 94-13-10

- Piper Service Bulletin 411A Stabilator Torque Tube Bearing Block Attachment Fitting Rivet Replacement.

- Piper Service Bulletin 464A Inspection of Stabilator Torque Tube Bearing Block Attachment Fitting Rivets. This is remedied by installation of the Piper Kit 760-835.

- Special Airworthiness Information Bulletin – CE-04-88

- Piper Service Bulletin SB-1160 Stabilator Torque Tube Assembly Inspection.

- Piper cover page – Torque Tube Replacement Kits.

Very informative article written by Denny Haskins of Redlands, CA. This really covers the horn issue well.

There is a “stabilator flutter” movie floating around on the internet. Scary!

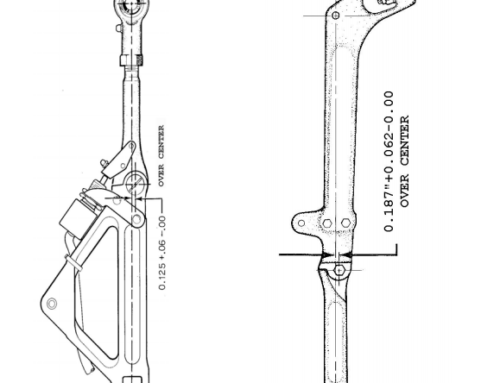

I’m in the process of writing another methodology, this one for the stabilator: lots of color photos, do’s and don’ts, replacing the bearings, horn forging treatment, trim drum clearance, setting the stops, and balancing. It will probably include the loan of the special tools to make life simple. Why? If you attempt this operational procedure using the Service Manuals as your reference you’ll find that confusion sets in because of the need to jump around the SM to different sections. My writing will have it in one place. Stay tuned, pending the FAA action expected!

Contact Comanche Gear

Please provide your complete details for invoicing such as your Card Billing Address, Shipping Address, and Aircraft Information. If you want to gab on the phone don’t hesitate to call, especially if you want to order something. If you have a problem-solving dilemma I can help with that too. This website doesn’t have internet ordering capabilities; that is for those more sophisticated. My email isn’t shown here because of scam artists and other shenanigans.