Name withheld:

I know this recommendation may have some self-interest “flavor” to it, for which I apologize. It’s well known that I am strongly committed to Comanche preventative maintenance, especially in the areas where there are known issues, and the landing gear is probably the most significant. My company is named appropriately.

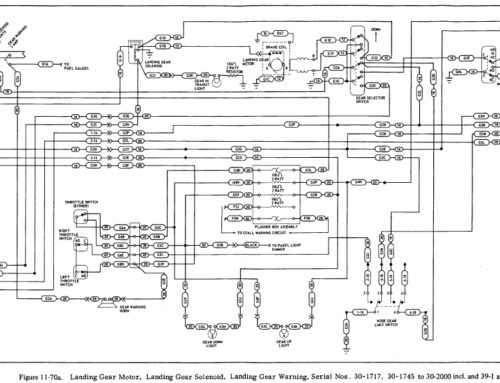

You are tackling the big landing gear AD and have a document as a guide; SL782B. I have been involved in many conversations concerning the somewhat related issue of replacing the landing gear retraction push-pull cables [conduits]. Many people don’t want to face the potential problem of trying to find someone to do the job, and you know the rest of the story. I have written a very thorough guide covering the replacement of the conduits and subsequent adjustments. Some of our airplanes are getting pretty old and I would beg you to name a significant component that has not been lubricated since new, nor easily could be lubricated; the conduits. That guide is available and should lead a sensible mechanic, capable of following instructions, to a successful completion of the replacement and adjustment procedures. The Comanche service manuals are vague and in places just plain wrong.

The conversations I hear usually have references to the lack of qualified shops and experienced mechanics familiar with the Comanche landing gear system. That issue and finances are the big resistance factors. The Webco conduits installed are an asset and will add to the value of the airplane, also when sale time comes they will be well-accepted and not an item on the squalk sheet.

If you can interest a couple more Comanche owners it becomes economical to have me there to do a group install.

We just don’t need any more gear collapse statistics. I’m trying to plant a seed; not beat on you.

Best Regards,

Matt

Here’s another Comanche owner who believes the conduits even after 40 years are as good as new.

After takeoff tonight, the gear wouldn’t come up….motor breaker tripped. My battery is 4 years old (G-35), tested at 82% in March and I hadn’t flown for about 4 weeks. It did turn over fine for starting however. My conduits are original, however, they are in almost new condition with no noticeable friction at all. Harness is original and should probably be replaced. Motor was overhauled several years ago and has had relatively few cycles since. Plane hasn’t had any gear issues for 40 years until today. How important is battery condition to the gear system? Is it possible that a weak battery caused the gear motor breaker to trip? Where should I start to troubleshoot this? Thanks. 1968 PA-24-260B

Edit 10/3 08:30 CDT – Time flies! Apparently the gear motor/transmission was replaced with a new unit in 1975 after 865 hours since new. I guess it may be due as well.

Name withheld:

To All [from Matt – that would be me]:

Read the Conduit Installation and Adjustment Manual carefully please.

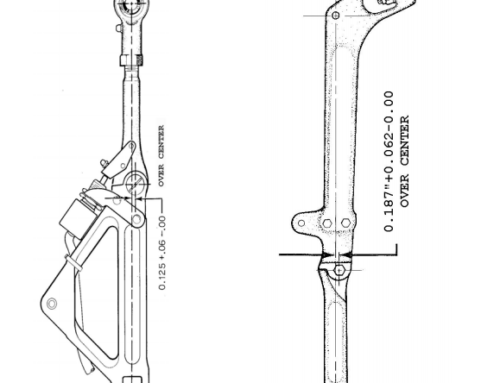

I recently had occasion to fly to a well-known FBO [to deliver a part for an AOG customer] who had just bought the above manual, tools, and all the hardware. It was a very scary installation indeed. No pre-load on the mains [how can that be!!]; and no evidence of even attempting to adjust the nose gear preload [paint undisturbed on the old hardware even though I supply all new hardware].

I asked the A&P if he read the manual, “yes” of course was his answer. I asked well then why didn’t you do the installation accordingly? He had the conduits routed incorrectly at the spar; some of the old hardware had been reused even though he had new in the kit, the cushioned clamps for the conduits and hardware were not installed correctly.

I took a lot of my time to write that manual and take the pictures and make all the notes for those photographs, essentially making it as simple as can be expected for a man to understand. Here’s one of my theories; if it doesn’t have a bell, a flashing red light, or big tits on it, a man just isn’t going to notice it. So it’s my self-appointed duty to get him to pay attention; I try. And by the way, the owner of the FBO thanked me for chewing the A&P’s ass. I reiterated to the FBO owner that I was for hire, which he knows already and has used my harness installation service many times. With my services there is no wasteful learning curve and it’s guaranteed to be done correctly. His repeated response was that he can’t afford me. But he can afford to do it twice; uh huh! I have full understanding of the issue, whether the job gets done correctly by a first-timer depends on whether he/she has that understanding and can read and follow instructions. I am a hard-ass when it comes to this stuff! Do it right or I’ll haunt you.

And so goes the old worn out adage, “why is there never enough time to do it right the first time, but always enough time to do it again?

More:

On another occasion I’ve witnessed a well-known FBO Comanche specialist who clearly didn’t intend to waste time doing the 1000-hour gear AD per SL782B. The nose gear drag links have a very detailed and specific checking and adjustment requirement; that requirement was not adhered to.

The owner of the aircraft though undoubtedly will swear by the service facility and the fact that it was done correctly. Uh-huh again! This may be driven by the intent of the FBO to save the owner money, maybe. I think it’s from lack of knowledge.

Contact Comanche Gear

Please provide your complete details for invoicing such as your Card Billing Address, Shipping Address, and Aircraft Information. If you want to gab on the phone don’t hesitate to call, especially if you want to order something. If you have a problem-solving dilemma I can help with that too. This website doesn’t have internet ordering capabilities; that is for those more sophisticated. My email isn’t shown here because of scam artists and other shenanigans.