Owner-Produced Paperwork Required

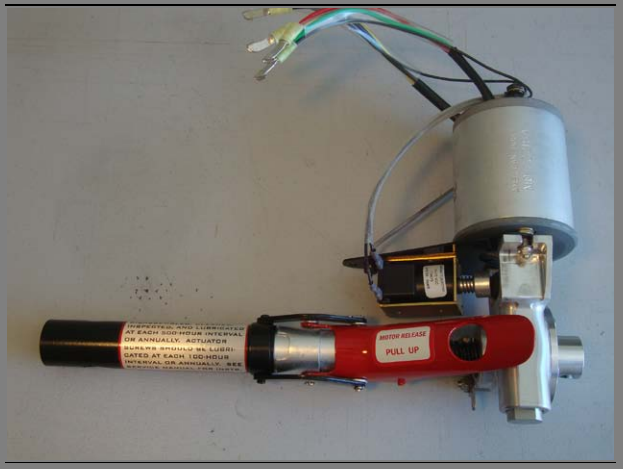

Complete landing gear transmission assembly P/N 25720-000 with “overhauled” motor $4,700, exchange.

The “overhauled” motor is available separately for $675 exchange, see below. These motors have new field coils, rewound and dynamically balanced armature, new Kevlar pole shoe insulators, new springs and/or brushes as necessary, repaired brush holders as necessary, MIL-Spec wires, properly re-impregnated Oilite® bearings, and the housing has been cadmium plated. This is as close to new as you can get, maybe even better.

Brake Coil Assembly

Part Number 24948-000, this is the same for the flap transmissions application $255; includes reproduction owner produced rubber coupling.

The “overhauled” motor is available separately for $675 exchange, see below. These motors have new field coils, rewound and dynamically balanced armature, new Kevlar pole shoe insulators, new springs and/or brushes as necessary, repaired brush holders as necessary, MIL-Spec wires, properly re-impregnated Oilite® bearings, and the housing has been cadmium plated. This is as close to new as you can get, maybe even better.

After installation of your new transmission, ship your exchange but preferably within 2 weeks; I need the motor and release components for refurbishing.

Compare this to an exchange Dukes transmission if you can find one [I may have them available], which may not have any new components. I sold an original Dukes for $5,500 in 2020, which is the price that I was offered.

FWIW I have every component to repair the Dukes transmissions; all of my new transmissions use the latest Dukes specification gears set, not the original steel version. The bearings I use are SKF [Italy] and Nachi [Japan], no chinesium stuff here.

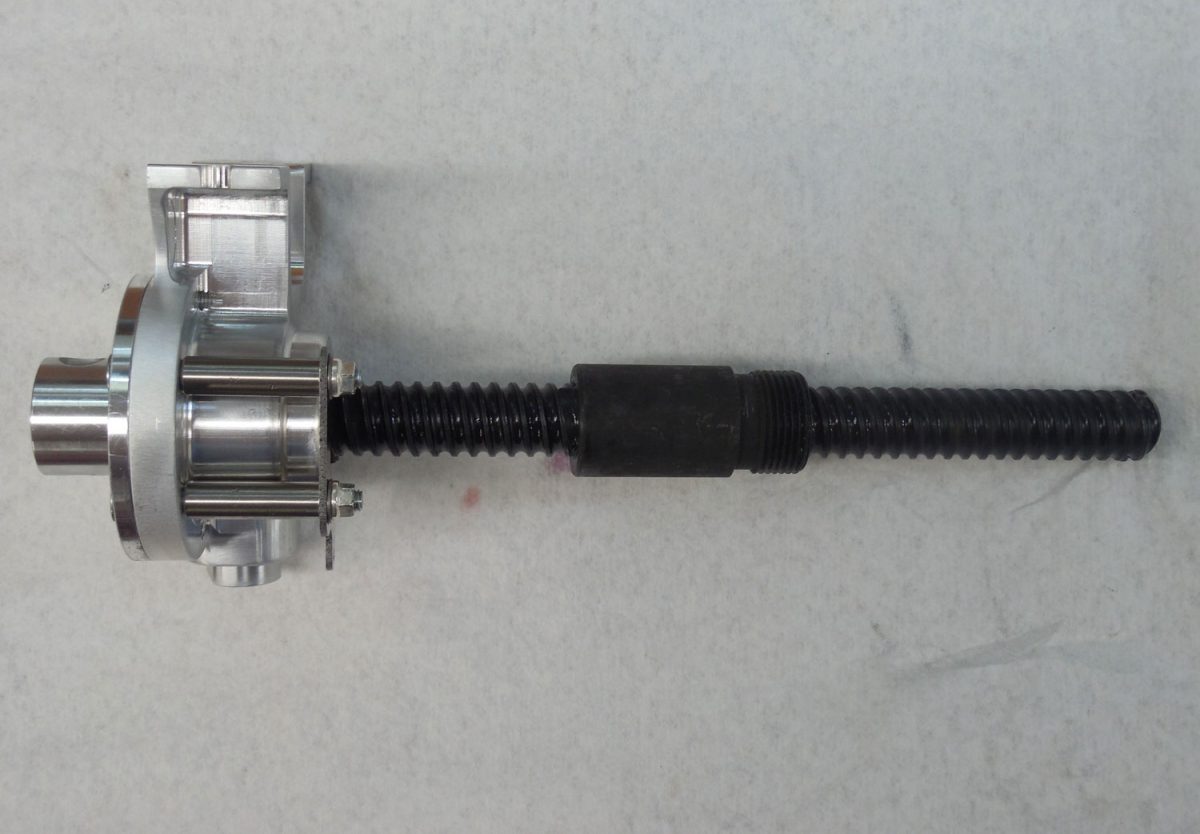

This dukes-type Piper Comanche landing transmission basic assembly P/N 25720-003 as shown below is $3,850 exchange, plus shipping and insurance. The black and red components are powder coated the other pieces are cadmium plated; also includes new placards. The updated bushing [safety issue] P/N 21038-007 is included, also owner produced.

If you have a new or guaranteed good motor, this transmission version is what you need. Install your motor and brake and you’re back in business.

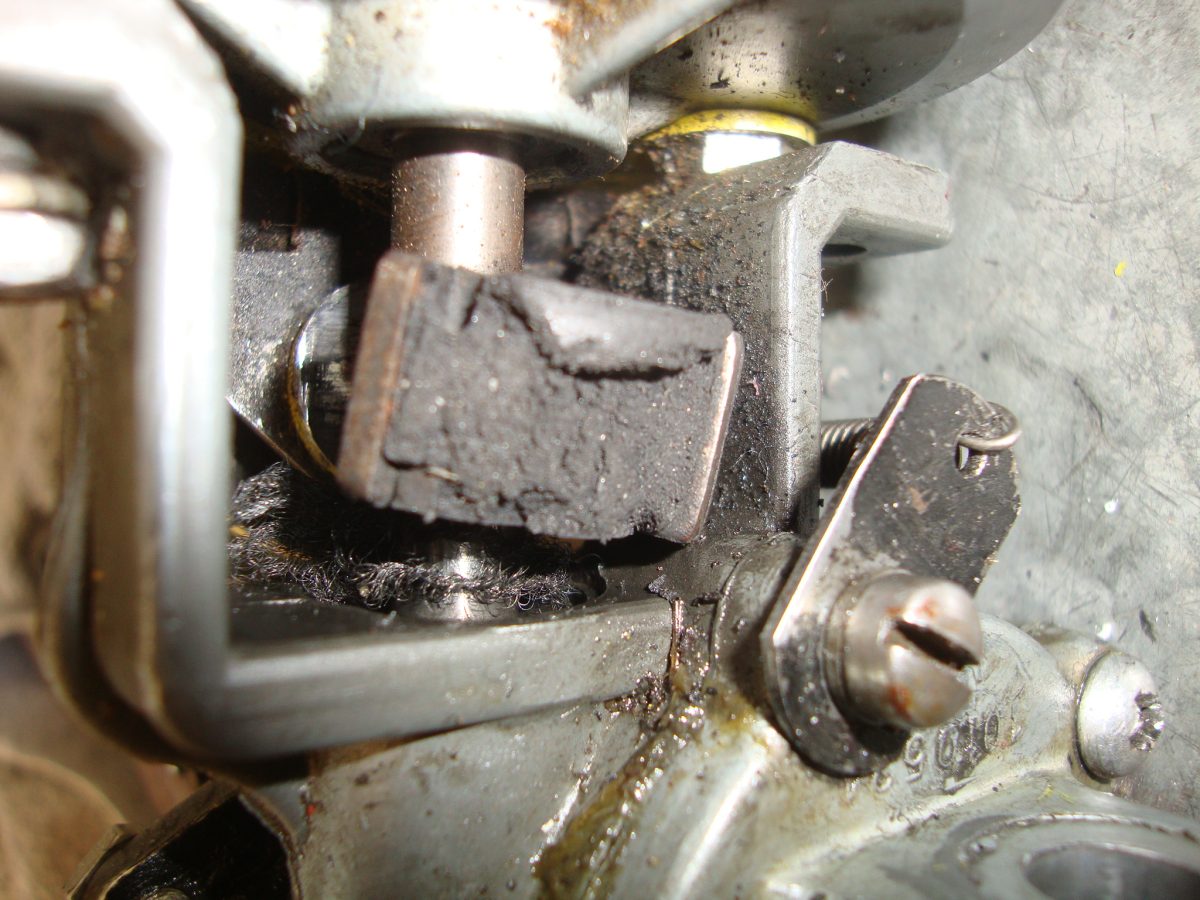

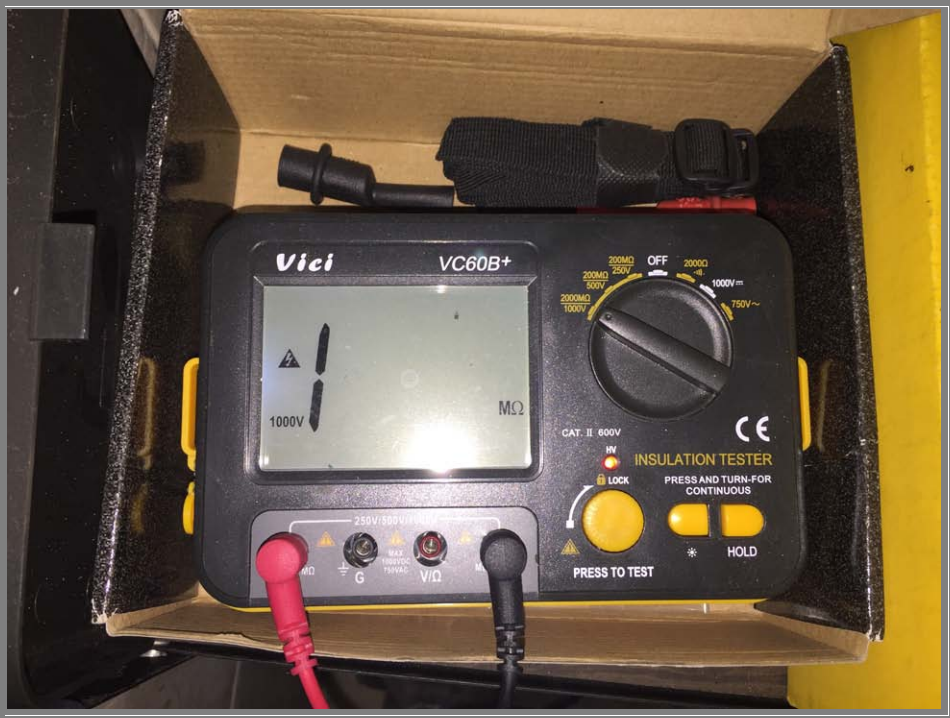

I hear a lot of, “Oh my motor is just fine.” Really? And who tested it with an insulation tester to determine that? Bad insulation leads to increased heat and current draw, sometimes adding to the 30-amp motor circuit breaker to open upon retraction

Don’t Let This Happen to You!

Comanche Gear Reproduction Rubber Coupling $75, owner produced. Piper’s price $536.20.

Considering these old motors have performed countless cycles, with 50 and some up to 70 years in service, in my opinion why ask another lifetime from one of them. This non-FAA “overhauled” [owner produced] unit is the problem-solver. Non-FAA because nowhere in either the Piper Comanche single or twin service manuals will you find mention of these motors nor the flap motors. Official FAA overhaul language would apply if there was stated criteria, and the agency was FAA approved.

Previously I was supplying motors from an FAA approved repair station, they developed the process at my request. After multiple failures and mistakes on their part, I pursued my own approach. The typical failure mode of the flap and landing gear motors is the insulation of the copper magnet wire windings in both the fields and armatures. Very few entering my shop pass this test, however some do especially if newer production date, or very low-time airframe.

An insulation tester is required to analyze the copper magnet wire insulation condition.

Similar service requirements apply as the original Dukes transmissions, i.e., 500 hour or annually; disassemble, inspect, and lubricate with Dukes specification #4 lubricant. The ball screw lubricant specified in the SMs is AeroShell® #7 at annual and 100-hour intervals; I suggest using Aeroshell® #64. AeroShell® #7 just doesn’t lend itself to longevity of ball screw life. Aeroshell® #64 contains 5% Molybdenum Disulfide, an extreme-pressure additive. The original ball screws would have survived longer with regular use of this grease; ball screws are a common failure.

All of my transmissions are supplied with new gears, new bearings, and a new ball screw assembly.

Same treatment as the landing gear motors, these flap motors have new field coils, rewound and dynamically balanced armature, new Kevlar pole shoe insulators, MIL-Spec wires, properly re-impregnated Oilite® bearings, and cadmium plated housing. This is as close to new as you can get, $625 exchange.

Just for reference, Dukes guesstimated between $7,000 and $8,000, but that was more than 15 years ago for the sub-assembly P/N 25720-002 pictured above, which is without the release arm components, motor, or brake asm.

This photo is for reference only, not for sale in this configuration. Since that quote the Dukes company was sold, and the price went into low orbit.

Contact Comanche Gear

Please provide your complete details for invoicing such as your Card Billing Address, Shipping Address, and Aircraft Information. If you want to gab on the phone don’t hesitate to call, especially if you want to order something. If you have a problem-solving dilemma I can help with that too. This website doesn’t have internet ordering capabilities; that is for those more sophisticated. My email isn’t shown here because of scam artists and other shenanigans.