INSTALLATION

It is important to watch a couple details upon installation of some components.

- At two locations there should be an extra-thick 5/16″ spacer/washer between the #21 air filter bracket assembly and the Bendix FI assembly SEE THE RED LINE. Please pay attention to this and the installation will be less prone to future cracking for the #22 “air filter box plate assembly” which is one of the problems I just repaired for you. I have provided this part for you.

- The 7 Camloc® latches must be secured to avoid an inadvertent unlatched condition. The factory tabs didn’t do the job which also contributed to the failure. If you choose to re-do the weight and balance; the repaired assembly weighs 4lbs 11oz, a gain of 1lb – 8oz due to the repair and 3 additional Camloc® latches.

MAINTENANCE for Continued Airworthiness

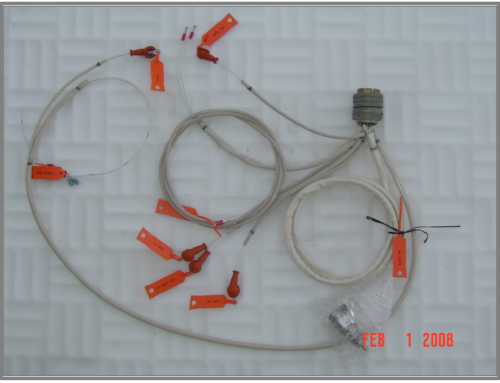

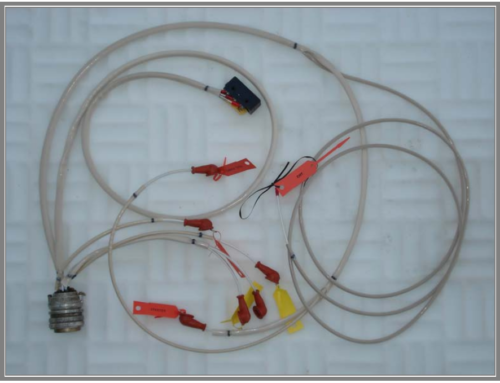

Check the condition of the Anti-chaff fiberglass tape around the circumference of the box cover and especially check the sealing silicone between the air box components; this is critical to the continued good performance of the air box assembly. The compression of this silicone material is important to avoid a loose condition. Also check the 7 Camloc® latches for proper adjustment; they must also be additionally secured. This lack of a good method to secure these latches was another reason this design from Piper was a bit weak coupled with no cushioning. I have had success with the lowly tie-rap, but safety wire sounds a bit more aviation-like and would probably make your inspector a bit happier too. See the information on the following page covering the maintenance materials which should be included in your annual inspection procedure.

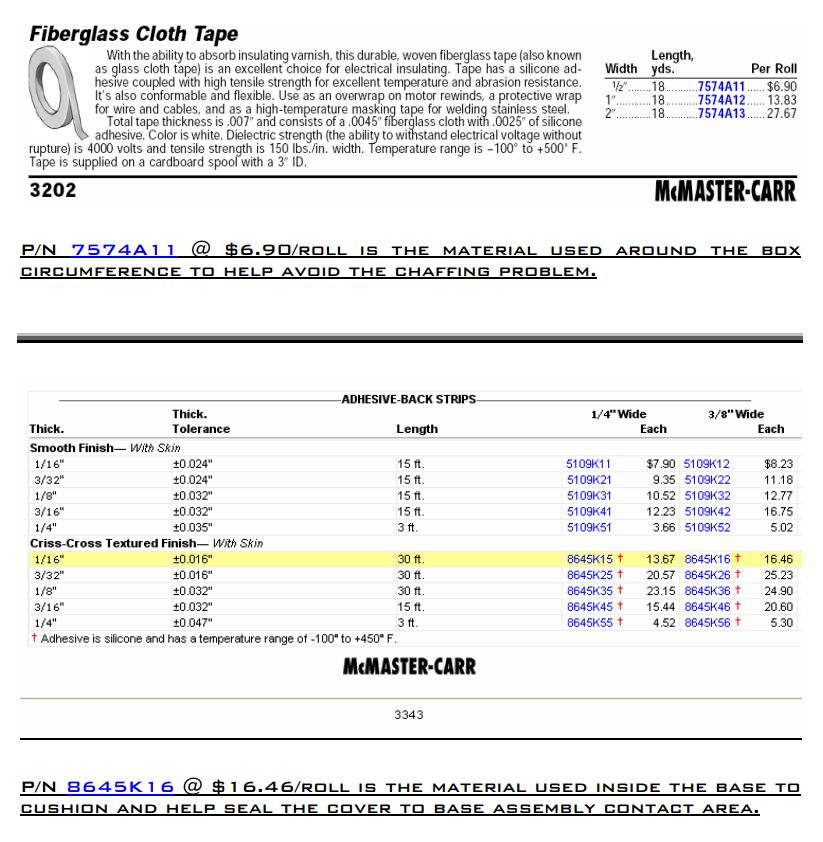

For the following maintenance materials, go to McMaster.com

The materials referenced here are subject to price change; I have merely included the information to assist you with locating these maintenance items.

Contact Comanche Gear

Please provide your complete details for invoicing such as your Card Billing Address, Shipping Address, and Aircraft Information. If you want to gab on the phone don’t hesitate to call, especially if you want to order something. If you have a problem-solving dilemma I can help with that too. This website doesn’t have internet ordering capabilities; that is for those more sophisticated. My email isn’t shown here because of scam artists and other shenanigans.